In the world of sewing, there are countless tools and machines designed to facilitate the creative process. Among these, the twin needle sewing machine stands out as a versatile and valuable option for both seasoned sewists and beginners alike. This unique machine offers a range of capabilities, allowing users to create intricate designs while enhancing the quality of their projects.

User-Friendliness

After completing your project, you can neatly finish the raw edges using a serger or a zigzag stitch to prevent fraying. Iron the seams and enjoy the professional finish that double stitching provides.

Some thinner materials will require a special kind of stitch and also a lower ironing temperature. Thicker materials might also need to be sewn in layers. This process requires a powerful heavy duty sewing machine that can easily reach through the material without breaking or bending the needle.

Conclusion

Now that your machine is set up, you can start sewing. Engage the presser foot and start stitching slowly. Keep a steady pace to ensure even stitching, and avoid pulling the fabric to prevent skipped stitches. Regularly check your stitching to ensure that both threads are flowing smoothly and that there are no tangles.

2. Zipper Foot Specifically designed for sewing zippers, this foot allows the needle to get closer to the zipper teeth, enabling a neat and professional finish. It can be used for both standard zippers and invisible zippers, expanding its versatility.

3. Ease of Use Many models come with user-friendly features such as automatic stitch settings, built-in thread cutters, and adjustable walking feet, making sewing simpler and more efficient even for beginners.

The presser foot is a crucial component that can elevate your sewing projects from basic to exceptional. By utilizing specialized presser feet, you can tackle a wide range of techniques, from creating buttonholes to intricate quilting designs. As you gain experience and confidence in your sewing abilities, consider expanding your collection of presser feet to unlock new possibilities and fully embrace the art of sewing. Each foot is a tool that allows for creativity and precision, ensuring your sewing journey is as rewarding as it is productive.

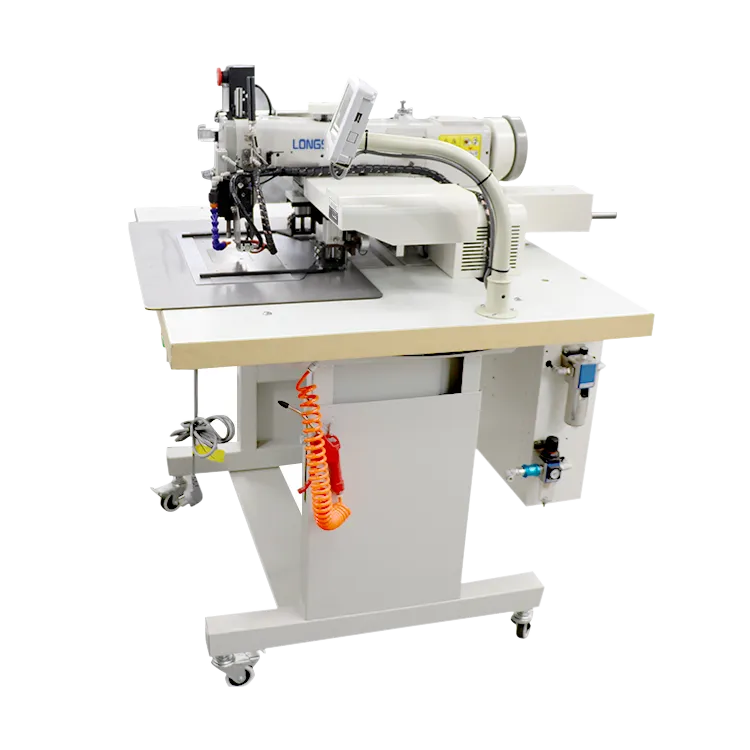

Understanding the Typical Double Needle Sewing Machine

Understanding Auto Sewing Machine Prices Factors and Trends

3. Quilting Needles Specifically designed for quilting, these needles have a tapered point that easily penetrates multiple layers of fabric.

In conclusion, sewing machine specials are an excellent way to acquire a new tool that can unlock your creative potential. By taking advantage of these promotions and considering your individual sewing needs, you can find a machine that will help you bring your projects to life. Happy sewing!

Conclusion

Conclusion

Another notable aspect of raised bed sewing machines is their adaptability to different types of fabrics. Whether working with delicate silks or sturdy denims, the raised bed design encourages smoother movement and stitching, resulting in a more professional finish. This adaptability makes raised bed machines an ideal choice for those who enjoy experimenting with different materials and sewing techniques, as they can easily switch from lighter fabrics to heavier ones without compromising on ease of use.

Cast Iron Body and Metal Parts

Design and Mechanism

One of the key benefits of arm sewing is its portability

. You can easily take your sewing project with you wherever you go, whether you are traveling, camping, or simply moving around your home. This flexibility allows you to work on your projects whenever inspiration strikes, without being tied down to a bulky sewing machine.arm sewing

Tools Required

The activity of GSC367TD is also regulated by various signaling pathways within the cell. For example, certain signals can trigger the phosphorylation of GSC367TD, altering its ability to bind to DNA and regulate gene expression. In this way, GSC367TD can act as a molecular sensor, responding to changes in the cellular environment to modulate gene expression accordingly.

Using a Heavy Duty Walking Foot Sewing Machine for Thick Fabrics

1. Sewing Machines Typically used in industries such as textiles and food packaging, bag sewing machines utilize industrial threads to stitch bag tops securely. This method is particularly effective for multi-wall paper bags, as well as woven polypropylene bags. The durability of the sewn closure makes it a preferred choice for heavy or bulk products.

bag closing machinery

The Pricing Landscape of Auto Sewing Machines

Heavy-Duty Sewing Machines: These machines are made for home workers who sometimes need to work with tougher fabrics like leather or denim. Even though they can handle more complex jobs than a regular home machine, they are not made for high-volume, continuous sewing.

One of the primary advantages of manual machines is their ability to create consistent and strong stitches. The manual feeding process allows for a greater sense of rhythm and timing, which can lead to a more uniform appearance. Moreover, since there is no reliance on electricity, these machines can be used in any setting, making them ideal for workshops, outdoor projects, or anywhere where power sources may be limited.

4. Cost-Effectiveness While the initial investment in a double stitch machine may be higher than standard sewing machines, the long-term savings through increased efficiency, reduced fabric waste, and lower return rates can make it a more cost-effective choice.